How GM's Ultium Battery Will Help It Commit to an Electric Future

When GM launched the plug-in-hybrid Chevrolet Volt in 2010, the auto industry talked about battery cost around $1000 per kilowatt-hour of energy storage. At that price, the Volt's 16.0-kWh pack was likely more expensive than all other components of the car combined.

Now, with GM's latest battery, dubbed Ultium, the company says it's approaching a cost that's 90 percent lower—a point where it can finally be profitable to shift away from internal-combustion engines. The automaker has promised to do just that, launching 30 new EVs around the globe by 2025. Come 2035, its only vehicles with tailpipes will be heavy-duty trucks.

The building block for this plan is a large, pouch-type lithium-ion cell, roughly 23 by 4 by 0.4 inches. It weighs about three pounds and contains 20 times more energy than Tesla's small, cylindrical cells. (Teslas currently have thousands of battery cells in their packs, whereas EVs from GM and most other automakers have hundreds.) The 0.37 kilowatt-hour of gross energy capacity in each cell is enough to propel the first Ultium-powered vehicle—the mammoth 2022 GMC Hummer EV pickup—just over a half-mile. These cells will be produced in a joint venture with LG Chem at two massive new facilities in Ohio and Tennessee. When both plants are up and running by the end of 2023, they'll be able to create a combined 70 gigawatt-hours' worth of batteries every year. That's the equivalent of roughly 190 million cells, or enough for about 750,000 vehicles, by our estimates.

LG has been GM's go-to battery supplier for over a decade, during which time both the size and chemistry of the cells have evolved substantially. Compared with the cell used in the Bolt EV, the Ultium cell, a nickel-cobalt-manganese-aluminum blend, has 70 percent less cobalt, a key to reducing cost. Any LG customer can buy this cell, though, so whatever competitive advantage GM leverages will have to come from how it integrates components into a complete pack. The packs will have net capacities between 50 kilowatt-hours (144 cells) and 200 kilowatt-hours (576 cells), put out between 235 and 1000 horsepower, and provide up to 450 miles of range.

GM claims it's the only automaker right now that can either lay cells flat or stand them upright. That gives engineers flexibility in shaping a pack to follow a vehicle's floorpan. GM bundles the cells into groups of 24, creating a module. In the Hummer, 12 modules are wired in series to make one 400-volt, 100.0-kWh layer of a double-stacked battery pack. The two layers are connected in parallel to arrive at a total 200.0-kWh net capacity.

Here's the neat trick: On some Ultium vehicles, such as the Hummer, the top and bottom layers can be temporarily switched from a parallel to a series connection, doubling the voltage to 800. This lets it take full advantage of the highest-output 800-volt Electrify America fast-charging stations. Fittingly, the Hummer's ability to charge at 350 kilowatts means it can draw electricity quicker than any EV on the market today. By switching the pack from 400 to 800 volts for fast-charging, GM avoids paying for the more expensive componentry that's required for an EV to operate at the higher voltage all the time, as the Porsche Taycan does. The Taycan is currently the only EV out there that's capable of charging at 800 volts, albeit at a lower 270-kW peak.

DC fast-charging, as well as repeatedly topping up a battery to 100 percent, is the most common cause of the degradation that reduces a battery's capacity over time. That speedy charging can cause fast-moving lithium ions to crystallize in the cells, preventing them from moving back and forth as the battery charges and discharges. But Tim Grewe, GM's global electrification and battery systems director, makes some bold claims for the Ultium pack. He says no amount of DC fast-charging will degrade its capacity, and unlike Tesla and others, GM will not suggest the pack be charged to less than 100 percent during normal daily use. He credits the breakthrough to the careful development of the chemistry, including the addition of aluminum into the cell. Grewe also promises that the Ultium pack "will last longer than the Bolt EV's," which he says is making it to between 150,000 and 250,000 miles in the real world, comfortably past its 100,000-mile warranty.

Typically, automakers need a throng of wires to monitor the hundreds of individual cells in a pack. But GM found a way to monitor the Ultium's wirelessly. Each group of two or three cells wired in parallel broadcasts key information such as temperature and voltage several times per second. This reduces the pack's wiring by 80 percent compared with the Bolt's—eliminating a source of warranty claims, improving packaging, and simplifying the wiring harness. Plus, GM claims this setup consumes no more power than a wired system.

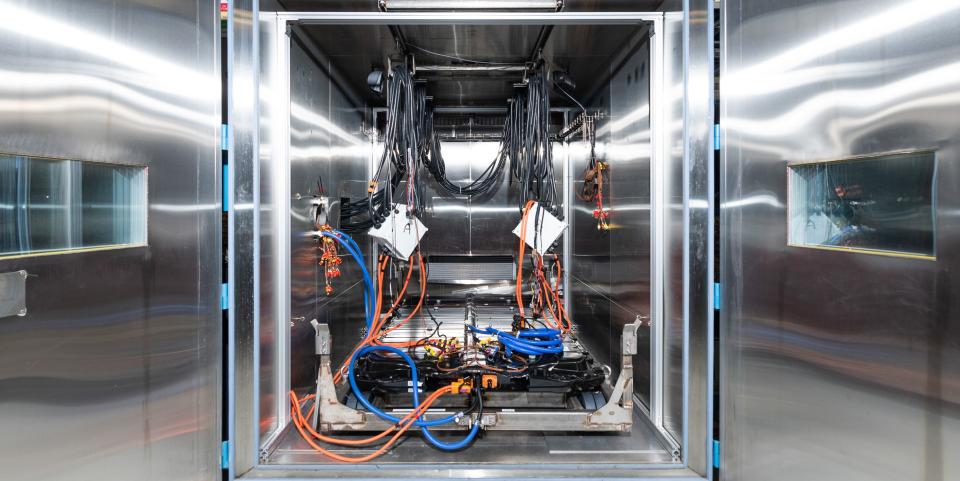

GM develops and tests the packs in its 100,000-square-foot battery lab in Warren, Michigan. The company's 75-ton megashaker looks like a 10-by-10-foot oven perched atop a platform. It jostles a battery around while varying temperature and humidity to the extremes. In a matter of a few days, this exercise imitates the abuse a battery takes from a lifetime of driving over potholes. Elsewhere in the massive lab, packs are charged and discharged repeatedly to simulate a full life cycle. They're subjected to puncture tests and dropped from heights of six and 16 feet to ensure, among other things, that Hummer owners can confidently peacock off-road. Engineers are also learning from the competition: On the day we visited, we saw a workbench full of components from Tesla and Jaguar battery packs.

While GM hasn't yet sold a vehicle with an Ultium pack, the lab is already hard at work on the second-gen cell. Grewe suggests it could as much as double this new cell's energy density. With costs now coming under control, the next big challenge in battery technology is stretching the range and slashing the weight of today's packs.

You Might Also Like

Yahoo Autos

Yahoo Autos