This Old Bike, Part 1: How We Upgraded the Suspension on Our R6 Project Bike

When I decided to bring my old track bike back to race trim, the first order of business was the suspension. Many moons ago, I had the forks built up with GP Suspension internals and installed an Elka 3-way shock. The improvement in feedback and feel on the track was a revelation, and transformed a well-mannered street bike into a competent track weapon. But contrary to every piece of advice I had heard (and dutifully repeated), I just rode the bike after that, never bothering with suspension maintenance other than the occasional wipe-down. I know, I know, shame on me. But the leaking shock finally forced my hand, so it was time to head over to see Matt Carr at Ducati Indianapolis, to see if he could undo the years of neglect.

READ MORE: The Basics: Modern Motorcycle Suspension | RideApart

A proper motorcycle shop: clean, organized, and well lit.

The Shop

Matt and his father Bill have been in business in Indy since 2007, but Matt's industry experience reaches back to his 1997 graduation from MMI in Orlando. He began racing with CCS the same year, outfitting his own bike with an Ohlins shock and rebuilt forks. He was an immediate student of suspension technology, tuning his own bike at the track and reading everything he could get his hands on regarding the topic. Soon he was working as a suspension tech for shops and dealers in the Chicago and Detroit areas, which he did for eight years before making the jump into his own business with his dad. Along the way, he trained extensively with Ohlins, GP Suspension, LAKO Performance and RaceTech.

When I wrote about what you should look for in a shop, Indy Ducati was the place I had in mind. Their shop is immaculate, their service is impeccable, and their reputation among the local riding and racing community is unsurpassed. They sponsor racers and hold track days at Putnam Park, where Matt spends much of his time providing suspension setup and tuning for every rider on every type of bike, regardless of whether they're a customer of Indy Ducati. They also host community events, including an annual party during the Indianapolis GP weekend.

The reputation enjoyed by Indy Ducati in the midwest motorcycle scene has as much to do with their business philosophy as their technical expertise. The purpose of any business is to make money, of course, but Bill and Matt made the conscious decision a long time ago that it wouldn't be their sole focus. They got into the business because they are passionate about motorcycling, and wanted to share and encourage that passion with others. That philosophy has meant more than a few sleepless nights, and a whole lot of evenings and weekends working, when they'd rather be out riding. But that's all part of what they accepted when they took on the challenge. "It's a family business," Bill says, "and we look at our customers as extended family. There's nothing magic about the Golden Rule. It's all about the customer, and that's what we drive home with anybody that works here."

Removing the fork cap.

The Fix

Matt agreed to take on the task of rebuilding my ailing bouncy bits, and let us in for a sneak peek at the process. As I came to find out, a proper suspension rebuild can become more of a detailed overhaul than a simple oil and seal change, and the result is a suspension system that works as good as new, or better. It's something often ignored by even the most nitpicky of riders, simply because of the downtime, cost and complication involved. Carr estimates that for every set of suspension he sees in his shop, there are hundreds more running around on the track and the streets that need service.

"My recommendation for track bikes is every 1500-2000 miles," he says, "with absolutely no more than 2000. For street bikes, every 12000 miles will do." He says that more frequent fork oil changes are beneficial, but "literally no one ever does it," even his most diligent customers. At least I'm in good company, right?

Having your suspension rebuilt isn't the cheapest or quickest service, but it is a necessary one. For less than the cost of the last couple sets of tires you sent to an early grave because of your neglected forks and shock, you can have them restored to showroom performance. This will pay dividends in handling, safety and tire wear, not to mention bringing the pep back into the handling of an old bike like mine.

Matt takes copious notes on every piece of suspension he services.

The first step in what is a long and meticulous process happens before a wrench ever leaves a tool drawer. Matt cleans, measures and inspects the external parts, examining the polished surfaces for damage and corrosion. He carefully records the fork length, damper and preload settings, so that he can return your parts to you with the same settings they had when they arrived. If you are changing valving or spring rates as part of the service, those settings will obviously be different, but in this case no such changes were made. He also checks the operation of the fork itself, to find out if there are any existing problems he should be looking to correct.

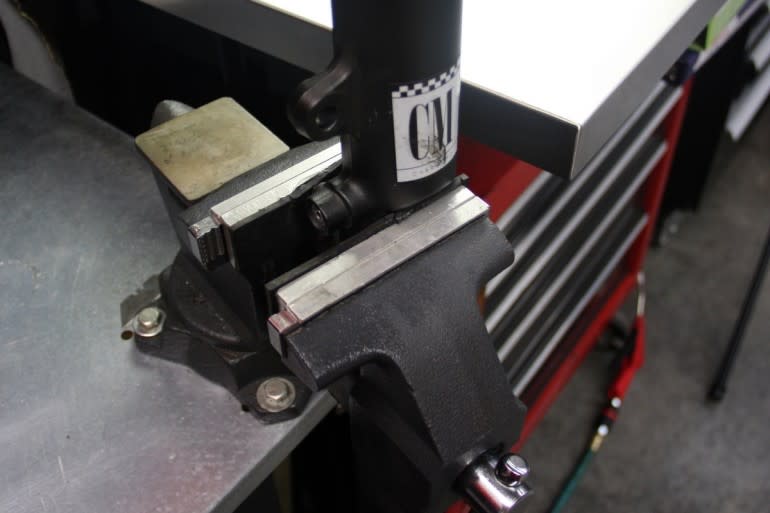

Rubber-padded aluminum vise jaw covers ensure your parts aren't scratched or damaged.

After removing the fork cap, Matt pours the old fork oil into a measuring container to check the volume and condition of the fluid. A small amount of metal flake in the fluid is to be expected, but larger bits may indicate failing components. He then carefully removes the fork internals, inspecting each piece as he goes, and laying out the parts to make sure nothing is missed, dropped, or reinstalled in the incorrect location during reassembly. For someone who has serviced hundreds upon hundreds of forks, this may seem an unnecessary step, but Matt has learned that his meticulous method saves time and prevents mistakes.

READ MORE: How to get Started in Minimoto USA - RideApart

The dust seals were hiding some ugly corrosion.

These seals have seen better days. It's a bit of a miracle the forks weren't leaking.

The seals will be replaced, and any residual rust is removed with a Dremel and wire wheel.

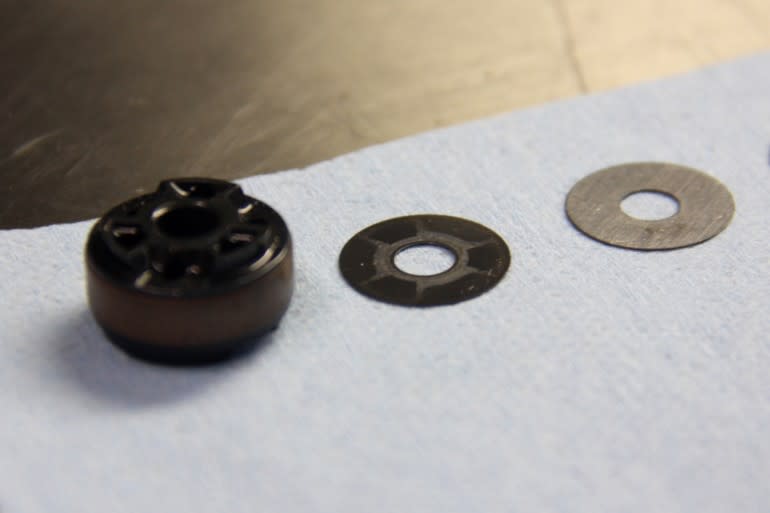

Special attention is paid to the shim stacks, the critical parts of each damping circuit. The shims function as a variable check valve during fork travel, their diameter and flexion carefully calibrated to provide the desired resistance to passing fluid. The tolerances for diameter and thickness on each individual shim are very tight, and their performance can be affected by the tiniest amount of damage or corrosion. Matt inspects and measures each shim, replacing them as necessary to restore the performance of the damping system.

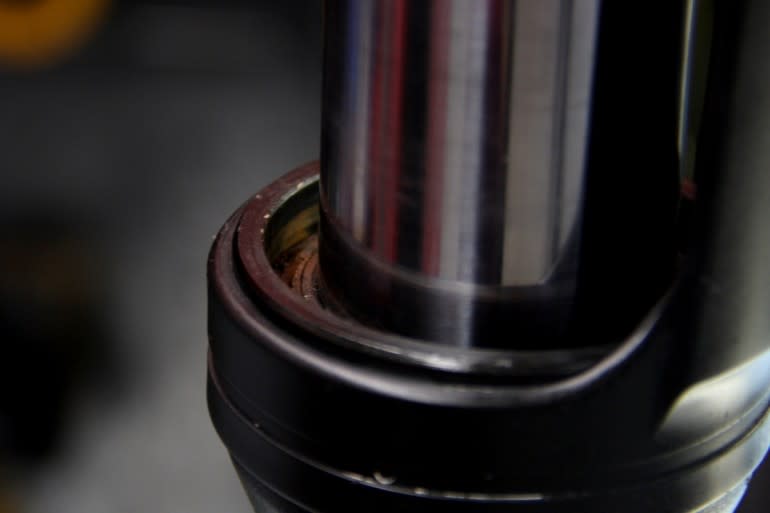

The GP Suspension compression valve assembly.

Matt lays out the shims in the order they were removed. Some of them can be very close in size, and mixing up the order will alter the operation of the valve.

The shim at center exhibits some of the mild surface corrosion that can alter flexion properties. This shim was replaced.

Each shim in every stack is carefully checked to ensure it is within tolerance and free of damage.

Once every piece of the fork has been cleaned, inspected, polished or replaced as necessary, it's time for reassembly. Matt prefers to use all new seals, as they're an inexpensive way to ensure that your newly rebuilt fork will perform as advertised and won't leak a few hundred miles down the road. The bushings that keep the inner fork tube centered in the outer tube are a wear-replaceable item as well, but in this case they looked fine for continued use. If a spring change is in order, the spring spacer may be exchanged for one of a different length to achieve the desired preload characteristics.

Compressed air is used to flush debris from the reassembled valve before installation.

The rebound valve is reinstalled on the damper rod.

On the left, new fork oil. On the right, fork oil that should've been changed a long, long time ago.

Matt sets the proper fork oil level.

New seals, snap rings and dust seals.

It's about the details. Scuffed decal? That's getting replaced too.

Continue reading on Page 2

Follow RideApart on Facebook and Twitter, along with @RideApart on Instagram.

Rebuilding the rear shock is a similar process, but with the addition of a pressurized reservoir. This part consists of a cylinder with a free-floating piston that separates a pressurized air charge on one side, and hydraulic fluid on the other. Since the fluid circuits in a shock are a sealed system, it is imperative that all air is removed from that side of the system, and that the floating piston seals correctly in the reservoir. Failing to accomplish this can lead to a shock that feels spongy, or even performs erratically.

The shock, deconstructed.

Same story as the forks. The used shock oil on the left is long past its expiration date.

The compression valve and adjustment assembly, reinstalled.

The rebound shim stack. Fluid will flow through the ports on the valve when sufficient pressure is reached to flex the shims. Changing the diameter or number of the shims changes the flow rate and pressure needed to open the valve.

Matt intentionally overfills the reservoir before installing the piston, to help ensure as little air as possible will need to be purged. It's a messy step, but a necessary one.

The rebuilt shock, ready for testing.

Once the shock has been through the same painstaking process of disassembly, cleaning and inspection, Matt installs new seals and begins reassembly. The compression and rebound valves are reinstalled, and the reservoir filled and purged. Matt fills the pneumatic side of the reservoir with nitrogen, and then the shock is ready to be tested.

Testing the rebuilt shock on the Roehrig dyno.

One piece of equipment that sets Indy Ducati apart from many shops is their on-site shock dyno. Roehrig supplies top NASCAR and IndyCar teams, and the electromagnetic shock dyno at Indy Ducati is a state-of-the-art system identical to those used by factory motorcycle road race teams. Carr and his team use it to functionally check a new shock build, and test the performance of the damping system over a variety of settings. The data generated by the shock dyno can be used to verify shim stack performance after a change, without having to take the bike to the racetrack and rely on the subjective feedback of a rider. Testing on the dyno is an optional service, but one that could save you many hours and hundreds of dollars if you're trying to diagnose a finicky handling problem, or dial in just the right damping for the track.

Reinstalling the spring with custom fittings on the hydraulic press.

After the shock was put through its paces on the dyno, Matt reinstalled the spring using a hydraulic press, and reassembly was complete.

Almost all riders overlook suspension maintenance on their motorcycles. Suspension performance usually degrades slowly over time, the changes almost imperceptible except by examination of tire wear. Rebuilding a set of forks and a shock can take half a day or more, once all of the required parts are on hand. The process is as meticulous as any surgery that can be performed on a motorcycle, and for good reason. The downtime involved can be an inconvenience, but I minimized this by having the service done in the offseason, and shipping my parts to Indy Ducati in inexpensive gun cases from a sporting goods store.

If you are like most of us, and haven't had your suspension serviced by a competent shop like Indy Ducati, now is the time to remedy the situation, before the riding season begins in earnest. It's an investment in the relationship between you, your motorcycle and the road, and one that will pay you back with crisper handling, longer tire life, and increased safety. The end result is a completely overhauled suspension system that will perform as well as brand new parts, giving your old bike a new lease on life.

An old shock, made new again!

All photos by Pete Hitzeman

Click on the link below to read the First installment of This Old Bike.

READ MORE: This Old Bike: RideApart's 2004 Yamaha R6 Project Moto - RideApart

Follow RideApart on Facebook and Twitter, along with @RideApart on Instagram.

Yahoo Autos

Yahoo Autos