2016 Acura NSX Tech Secrets Revealed

When it finally launches on the market, the 2016 Acura NSX will be one of the most advanced performance cars in production, a feat made all the more impressive when you factor in that you won’t need to be a millionaire to afford one (Acura hasn’t mentioned pricing but the sticker is expected to fall well below $200k). The individual components found on the car are impressive in their own right, but in the new NSX they’re combined in a sexy, mid-engine package that Acura assures us will also be one of the best-handling cars on sale.

DON'T MISS: Ford Moving Quickly To Ensure Cheap, High-Volume Carbon Fiber Production

We’re talking about a lightweight, multi-material spaceframe chassis in which a twin-turbocharged V-6 is paired with a nine-speed dual-clutch transmission and works in conjunction with a trio of electric motors powered by lithium-ion batteries. Yes, if you’re a tech head, your dream car has arrived in the form of the new NSX.

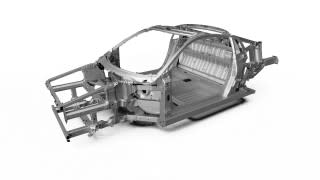

Starting with the chassis, the engineers decided on a spaceframe design that combined lightweight aluminum and carbon fiber with high-strength steel to boost rigidity while keeping weight down. But it’s not just about materials as the engineers also employed some advanced construction techniques, including the auto world’s first use of ablation casting, which results in the design flexibility and rigidity of traditional casting with the ductility and energy absorption characteristics of extruded material.

On top of this, the new NSX also features three-dimensionally formed ultra-high-strength steel A-pillars. This allowed the engineers to keep the pillars thin, improving visibility, while at the same time providing the strength to ensure the cabin remains intact in the event of a rollover. Finally, the aluminum-intensive spaceframe is complimented with a carbon fiber floor to add further strength and rigidity.

CHECK OUT: Stock 2015 Chevy Corvette Z06 0-185-MPH Run: Video

With the chassis sorted, attention was turned to the body, where airflow—for both aerodynamic needs and cooling—dictated how each panel was formed. Computational fluid dynamics was used extensively during development to allow the U.S.-based development team to maximize the performance of a powertrain being developed in Japan.

Yahoo Autos

Yahoo Autos