Volvo Preps Torslanda Plant for EV Production

Volvo invests $1.1 billion into Torslanda, Sweden, plant ahead of plans to offer an all-EV lineup by 2030.

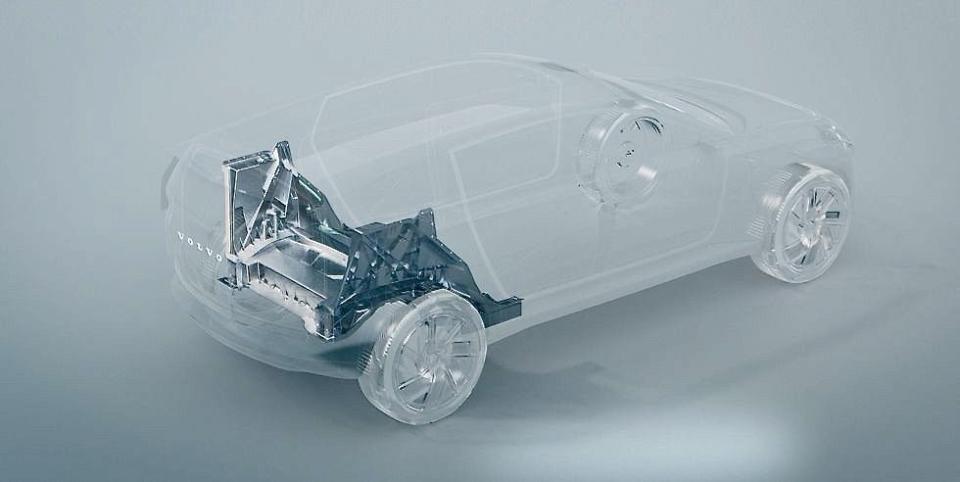

The automaker will adopt an aluminum mega-casting process, which will create large single assembly pieces instead of using many smaller ones, reducing complexity and lowering overall vehicle weight.

Volvo has recently chosen Gothenburg, Sweden, as the site of a battery gigafactory to be co-operated with battery specialist Northvolt.

Volvo's Torslanda plant is the automaker's oldest assembly facility that's still in use, in service since 1964, but it is by no means outdated. Just last year the plant achieved a climate-neutral status as part of Volvo's plans to make all of its factories climate-neutral by 2025.

Now, the automaker is investing around 1 billion euros to get Torslanda ready for EV production as Volvo plans its transition to an all-EV lineup in just eight years.

This week Volvo revealed it will introduce several new processes at Torslanda to make the jump to an all-EV future, just days after announcing a new gigafactory to be built with battery specialist Northvolt in Gothenburg.

A new major manufacturing process Volvo will introduce at Torslanda plant is mega-casting of aluminum body parts—creating major parts of the floor structure from a single piece of aluminum. This process reduces overall vehicle weight, complexity, and the overall environmental footprint of production, with one single piece able to replace dozens of individually manufactured and joined parts. It will also greatly reduce the time it takes to produce a major vehicle component.

Yahoo Autos

Yahoo Autos