Even the McLaren F1's Gearbox Has an Amazing Story

In 1992, the press release for the McLaren F1 went into great detail explaining what their new six-speed manual transmission was all about. It's worth reading in full:

Gear ratios offer an ultra close 5-speed cluster for 0-160mph, plus a 6th speed for 200mph-plus capability.

Wheelbase length in most mid-engined sports car designs is increased by conventional clutch and final-drive arrangements forcing the drive-output center rearwards. Until now, all attempts to minimize wheelbase length-such as sitting gearbox and final-drive beneath the engine-have compromised handling, weight or efficiency.

In conjunction with Traction Products Inc., McLaren Cars has imaginatively solved such problems, with the McLaren F1’s final-drive gear offset alongside its clutch, absolutely minimizing engine/drive output centerline separation.

This layout within a transverse-shaft gearbox-already inherently short front-to-rear-provides an exceptionally compact assembly within an extremely rigid cast magnesium casing accepting major rear suspension loadings.

The F1 is also the first production car to adopt current Formula 1 practice by featuring a 200mm diameter aluminum flywheel and carbon clutch assembly. Their extremely low mass and inertia greatly enhance engine response and efficiency, and also save weight.

The 6-speed gearbox has a full synchromesh gear change with helical gears for optimum strength, quiet high-speed running and quick and efficient gear-changing.

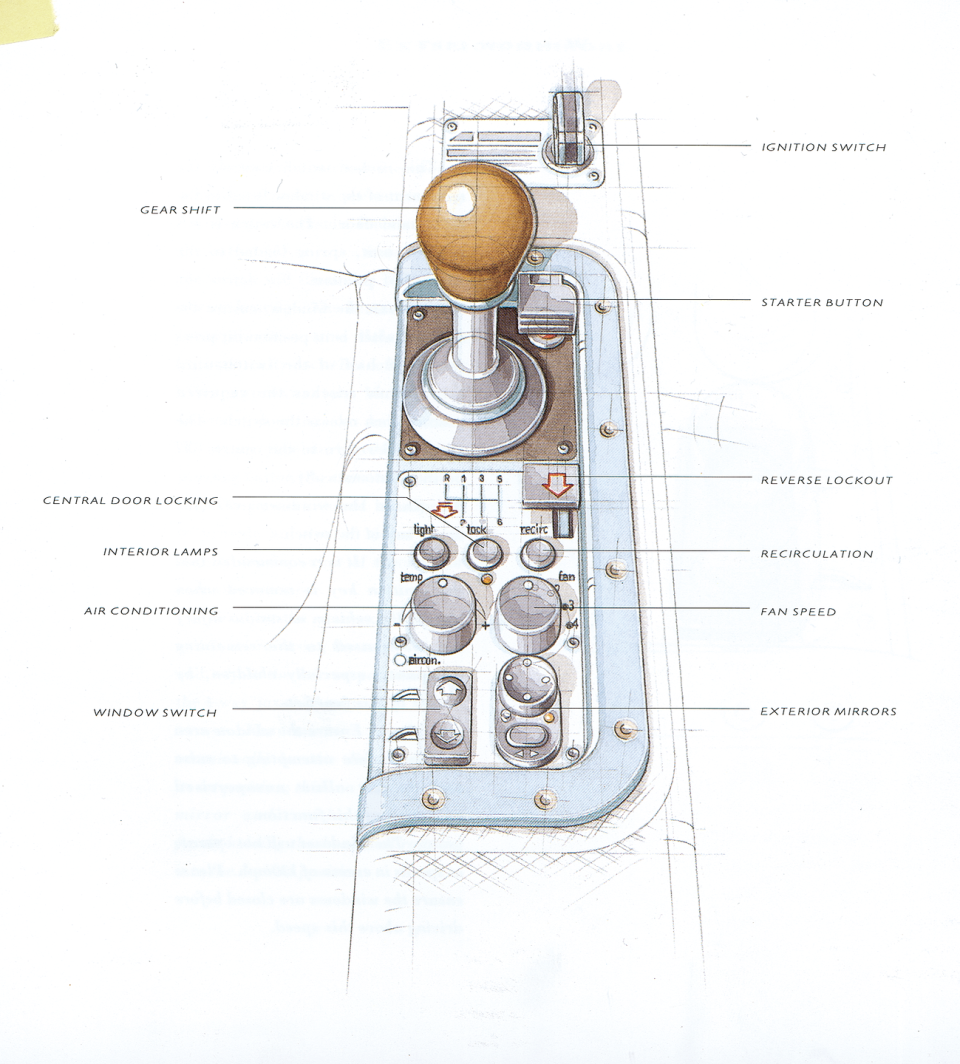

Further features include a sophisticated lubrication system, a remote clutch-operating mechanism tailored to provide optimum pedal weight and action, and an integrated purpose-designed starter system.

Gear ratios offer a close 5-speed cluster for 0-160mph (257km/h) plus a 6th-speed presenting a comfortable, peaceful and long-striding 33mph (53km/h) per 1,000rpm cruising gear-plus top speed capability well over 200mph (321km/h).

The final-drive assembly also features a limited-slip differential, while purpose-made constant-velocity jointed high grade alloy-steel drive-shafts are used.

As in all areas of the McLaren F1, exhaustive research and development effort has been applied to no-compromise design and manufacturing quality.

This week, I met Rainer Rump, who currently works as Head of Project on the BMW i8 Roadster. When asked how long has he been at BMW, he replied "over 40 years," adding that he spent the first ten years or so at the brand's Motorsport division. Just in time to get involved in the F1 project, on the gearbox side.

Since I knew Gordon Murray's benchmark for the F1's six-speed manual was the Honda NSX shifter, I asked Rainer whether Gordon's orders in the early 1990s simply went something like "make it feel like this."

Rainer smiled. "Yes, it was exactly like that!"

Apparently, the benchmark was Murray's personal NSX. The team's first challenge was that the S70/2 is a long engine, much lengthier than the V6 found in the Honda. With that in mind, the joint McLaren-BMW effort turned to California's Traction Products Inc., a racing gearbox specialist run by Pete Weismann and his wife. Murray knew that the McLaren F1, which would become the world's most expensive road car when it debuted, couldn't use a racing gearbox with straight-cut gears.

The solution came when they combined Weismann's gearbox design with the synchronizer sets straight out of the V8-powered E34 5-Series transmission, as well as BMW bevel-roller bearings. Three years later, the very same stock BMW synchros won at Le Mans.

But long before the GTR's victory in 1995, the first prototypes had major transmission overheating issues. One problem was that in order to keep the weight down, Gordon Murray wanted to retain the magnesium transmission housing. It had been mentioned specifically in the 1992 press release, after all.

Yet Rainer told me that the final housing had to be made of aluminum instead, specifically to cope with the heat at high speeds.

No surprise then that in 1998, Andy Wallace had this to report after breaking 243mph at Ehra Lessien in the McLaren F1 XP5:

"Gearbox temperature reached 130 degrees, everything else is fine."

But the heat wasn't the only challenge. The gearbox used AP Racing's triple-plate carbon fiber clutch. And because those plates added quite some drag, the racing technology made shifting the F1 anything but smooth. At the time, young Mika Häkkinen had just been lured to McLaren by Ron Dennis; the Finn happened to sum up the F1 prototype's shifting experience as "punchy." Punchy wasn't what Gordon Murray asked for.

However, by the launch in 1993, the clutch drag issue had been resolved, and the McLaren F1 debuted with a transverse Weismann box filled with BMW E34 synchronizers, produced in England by FF Developments near Birmingham. And it works just fine.

You Might Also Like

Yahoo Autos

Yahoo Autos