Explained: The Myriad Ways Modern Vehicles Control Body Roll

From the April 2018 issue

Physics tends to get its way. And when it comes to cars going around corners, physics says this: They should lean. The tires grip, the outside suspension compresses, and the body lists. Reducing that list is what roll-stabilization systems aim to do. During cornering, conventional anti-roll bars—steel rods that act as torsion springs connecting the left and right suspension members—transfer some of the force compressing the outside suspension members to the inside ones, which limits droop and decreases body roll. But because the sides are mechanically linked, a single-wheel bump encountered while traveling straight affects both sides, reducing ride comfort.

Innovations in roll-stabilization systems have tried to balance the competing priorities of flat cornering and optimal ride comfort by redistributing load between the outside and inside tires during cornering, and relaxing the connection between them when the vehicle is traveling straight. Some manufacturers do this by introducing energy into the system, and others use physics against itself. Take that, Newton.

Active Systems

Relying on sensors and a control unit to determine when the car is traveling straight and when it’s cornering, active systems use electric or hydraulic means to actively resist roll in turns.

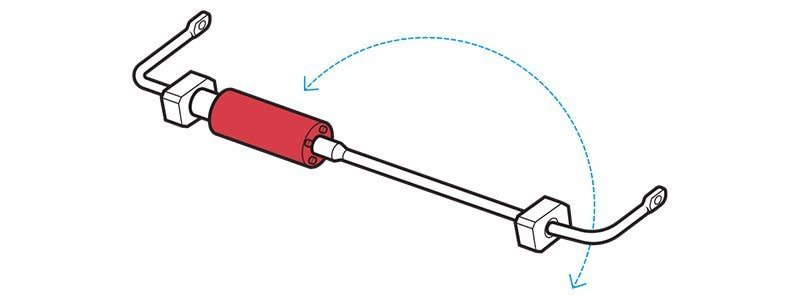

Split Anti-Roll Bar with Actuator

The most popular way to actively control body roll is to use conventional anti-roll bars that have been split in two. An electric motor or hydraulic servo between the two halves applies torque to each side individually and as needed. Bentley’s system is capable of fully decoupling the bars to enable greater wheel articulation off-road.

Applications: Bentley Bentayga; BMW X5, X6, and 5-, 6-, and 7-series; Lexus LC500 and LS500; Mercedes-Benz GLE; Porsche Cayenne and Panamera

[+] Easily packages into existing chassis.

[−] Hydraulic systems come with the complexity of plumbing, pumps, and valves; added mass; limited tunability.

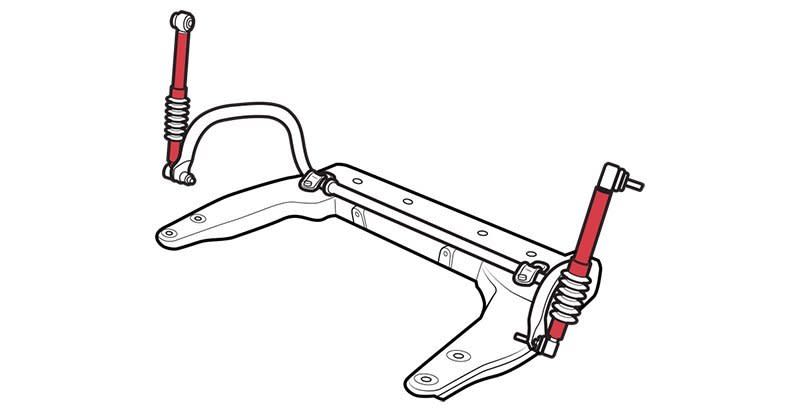

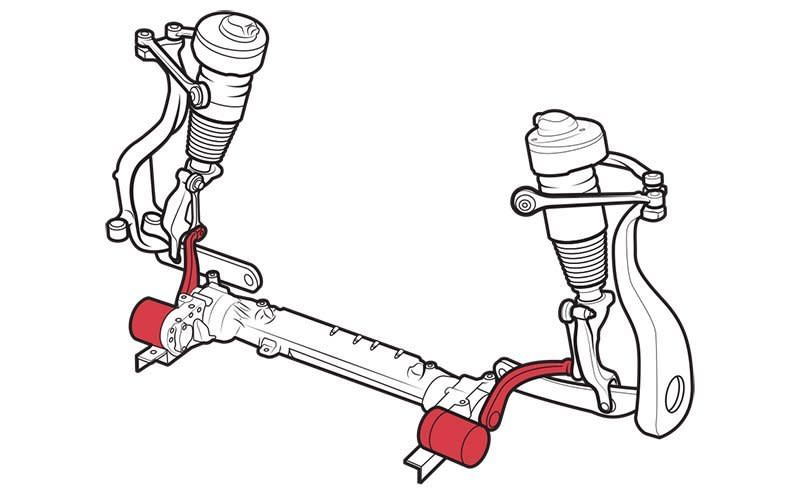

Active End Links

The Porsche Dynamic Chassis Control system, as it appears on the 911, uses hydraulic end links—actuators, essentially—on the anti-roll bars. The 911’s PDCC suppresses body roll by lengthening or shortening the end links during cornering.

Application: Porsche 911

[+] Compact, packages well.

[−] Hydraulic complexity.

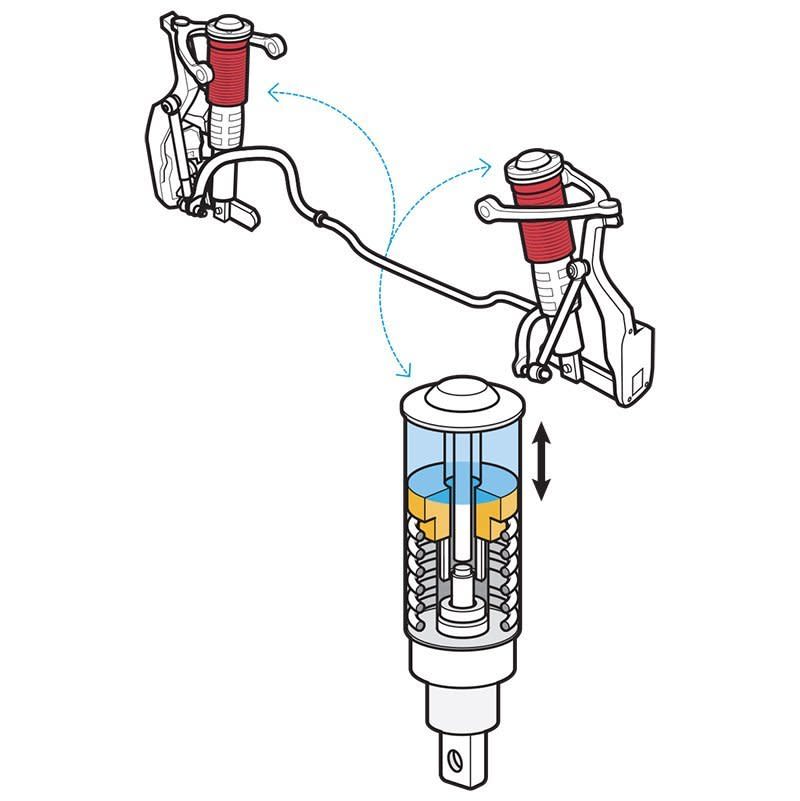

Mercedes-Benz’s Magic Body Control

To enable its Magic Body Control, Mercedes fits a hydraulic cylinder to the top of the spring-damper assembly at each wheel. When the vehicle corners, the cylinder extends or retracts—effectively lengthening or shortening the steel spring—to counteract body roll. The curve-inclination function can eliminate body roll and even lean the body another 2.7 degrees into a corner. Magic Body Control includes Mercedes’ Road Surface Scan, which uses a camera to spot unevenness in the road ahead and deploys the hydraulic hardware to help the wheels follow the road’s contour, reducing impact harshness.

Application: Mercedes-Benz S-class

[+] Multipurpose functionality.

[−] Hydraulic complexity.

Audi’s AI Active Suspension

Audi’s system is similar in concept to Mercedes’ Magic Body Control but uses electric motors rather than hydraulic cylinders. It replaces the anti-roll bars with a 2.7-hp electric motor at each corner coupled to the suspension via a torsion bar and working in conjunction with the standard air springs. Roll control is only one of the system’s functions. Its biggest virtue is its ability to minimize bump intrusion by anticipating surface imperfections and allowing the body to remain level like Mercedes’ system. It can also reduce brake- and acceleration-induced pitch motions and raise or lower the body for easier ingress and egress.

Application: 2019 Audi A8

[+] Multipurpose functionality.

[−] Multiple heavy components, including redundant springs.

Passive Systems

These systems don’t introduce any energy into the suspension to mitigate roll.

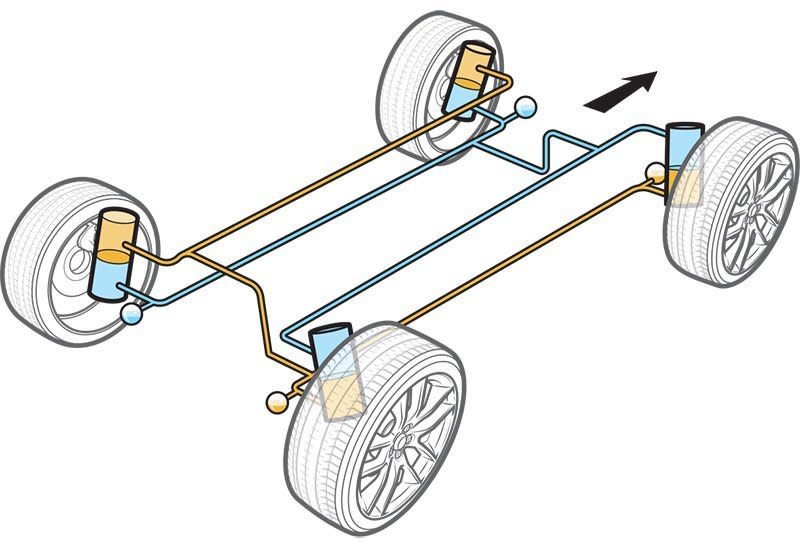

McLaren’s Hydraulically Linked Dampers

McLaren’s clever roll-control system links the compression chambers of the right-side dampers with the rebound chambers on the left side, and vice versa. As one side of the suspension compresses and the other side rises in a corner, the oil pressure increases within the interlinked system to resist roll. To change the roll stiffness between chassis modes, pressure within the system is increased or decreased via hydraulic accumulators.

Applications: McLaren P1, Senna, 650S, 675LT, and 720S

[+] Few electronic components, light weight, allows for truly independent wheel movement.

[−] Incapable of real-time roll-stiffness adjustment.

Lexus’s Roll Posture Control

Lexus uses its adjustable dampers in addition to conventional anti-roll bars to limit roll. During cornering, the dampers—capable of reacting in 10 to 12 milliseconds over a range of 650 adjustment points—effectively work like a pump, using small vertical wheel motions to jack up the outside suspension while squatting the inside, partially leveling the body.

Applications: Lexus LC500 and LS500 (active bars are optional)

[+] Uses existing hardware.

[−] Body roll must occur before it can be corrected.

Totally Disconnected

Jeep’s Wrangler Rubicon has offered the ability to electronically disconnect its front anti-roll bar since the 2007 model year. Decoupling on the all-new JL Rubicon allows a 30 percent increase in a two-door Rubicon’s ramp travel index. The system automatically recouples the bar at 18 mph to ensure roll control at road speeds.

Yahoo Autos

Yahoo Autos