Fiber Supplement: In Depth with the First Ever Carbon-Fiber Pickup Bed

Despite all the attention that automobile companies have placed on carbon fiber as an essential ingredient for cutting weight, boosting performance, and saving fuel, the material has a lot of issues that need to be solved-chief among them that it’s expensive to manufacture and hard to recycle. But with the debut of the 2019 GMC Sierra Denali and its CarbonPro pickup box-which, General Motors pointed out, is the first use of carbon fiber in a pickup bed-the automaker is convinced that it has cracked the code to making carbon fiber not just practical for the mainstream but sustainable.

According to Mark Voss, engineering group manager for advanced composites and pickup boxes at GM, the CarbonPro bed is the product of 15 years of carbon-fiber development at the company-dating back to the 2004 Commemorative Edition Corvette, which used a carbon-fiber hood. Work leading to the Sierra’s bed started in earnest in 2011. The beds are produced in partnership with supplier Teijin, at that company’s Continental Structural Plastics facility in Huntington, Indiana, near GM’s truck assembly plant in Fort Wayne.

This is no low-production-volume vanity project, Voss insisted, so we expect the bed eventually to spread to other trim levels of the GMC Sierra, as well as the Silverado. From the beginning, the intent was to go for high volume with a material that would stand up to the rigors of truck use.

“This actually started out as a mass-savings exercise,” recalled Voss. “But leadership challenged us to apply all those learnings in a way that makes sense for high volumes and breaks some of the cost paradigms-and it really brings us an affordable option for a pickup box.” Voss wouldn’t discuss the economics of it more specifically, or even talk about the cost relative to those other types of carbon fiber, but he did emphasize that the application makes it affordable to get materials advantages for bigger pieces such as this.

What’s Different

Two key decisions along the way make the carbon-fiber bed different from most other automotive applications of the material. The first was to go with a thermoplastic (in this case, a type of nylon) that is essentially heated and melted and then made in a compression mold, rather than using a sheet-molding compound or a thermoset that’s set and cured. The second was to go with chopped carbon fiber-in one-inch increments-rather than unidirectional or woven fiber.

The resulting material takes advantage of the strength of carbon fiber while allowing it to be used for complex geometries and sharp corners-including tight radii. With the process, GM can mold into the production version of the bed (existing trucks have shown it in prototype form) a more aggressive grain-kind of like sandpaper-at the top of the ridges, while the valleys of the ridges will be smooth for easy cleaning.

The result, GM insists, is very tough-tougher in most ways than steel. The beds have been tested for the dropping of heavy tools and optimized for impact-a strength for the isotropic material. And while there certainly is a temperature impact to thermoplastics like this material, supplier Teijin worked hard to essentially erase any variation that owners might see behind winter in Alaska and summer in Arizona. Voss said the box material is expected to outlast the rest of the truck.

Waste Not, Want Not

Considering that, the process allows a level of reuse that hasn’t otherwise been possible for carbon fiber. Reusing it involves none of the costly and labor-intensive separation of fiber from resin-or throwing away large chunks of material during production.

“We can take this, reform it, and do different things, to the point that there are actually two parts near where the front tie-downs are that are made of recycled pieces,” Voss said. “We literally take the scrap, shred it, and melt it.”

The potential to reuse and repurpose carbon fiber on a large scale isn’t nearly as easy with the thermoset methods you’ll find in McLaren supercars or the BMW i3. “You really can’t unfry the egg,” said Voss.

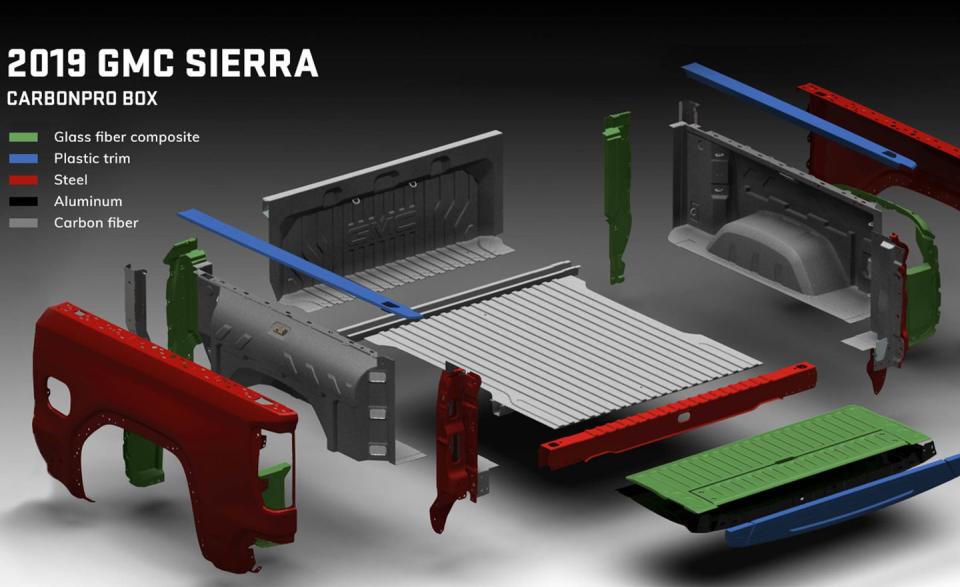

Voss described GM’s product as revolutionary “because it’s a thermal plastic, it’s structural, it’s UV stable, and it’s all these things that really the industry hasn’t done to date.” In terms of assembly, everything-attachment points and all-is 100 percent interchangeable between the steel-box Sierra and the CarbonPro one-except for the carbon-fiber bed’s lack of any need for paint. The only steel pieces in the carbon-fiber bed are the exterior panels and the rear sill (the wheel openings and tailgate use glass-reinforced nylon).

And the Sierra gets some serious mass reduction with the carbon-fiber bed. It cuts 62 pounds versus a bare steel bed-but with steel, the buyer would be likely to add a bedliner, so actual weight savings could be more than 100 pounds. That’s in addition to the standard model’s migration to aluminum for the doors, hood, and tailgate and more high-strength steel elsewhere to save up to 360 pounds versus the outgoing truck.

Lamborghini Forging Ahead; Checking Out Forged Carbon Fiber at The U.S.-Based Lab

Carbon Fiber from Plants Instead of Oil: Not Just Greener but Cheaper

Carbon Fiber Is Old News: These Materials Are the Next Frontier in Car Interiors

With mainstream-level costs, mass savings, and simpler reuse, GM might well have cleared up the carbon-fiber conundrum.

You Might Also Like

Yahoo Autos

Yahoo Autos