This Independent Firm Helps Automakers Reverse Engineer Competing Cars

For decades, automakers have sought to gain competitive intel by painstakingly disassembling rival carmakers' products to divine their strengths and weaknesses. It is a process that one former car-company engineer estimates costs about a quarter-million dollars per car. Compounded across the industry, where nearly everyone targets the same segment leaders, this benchmarking represents redundancy on a staggering scale.

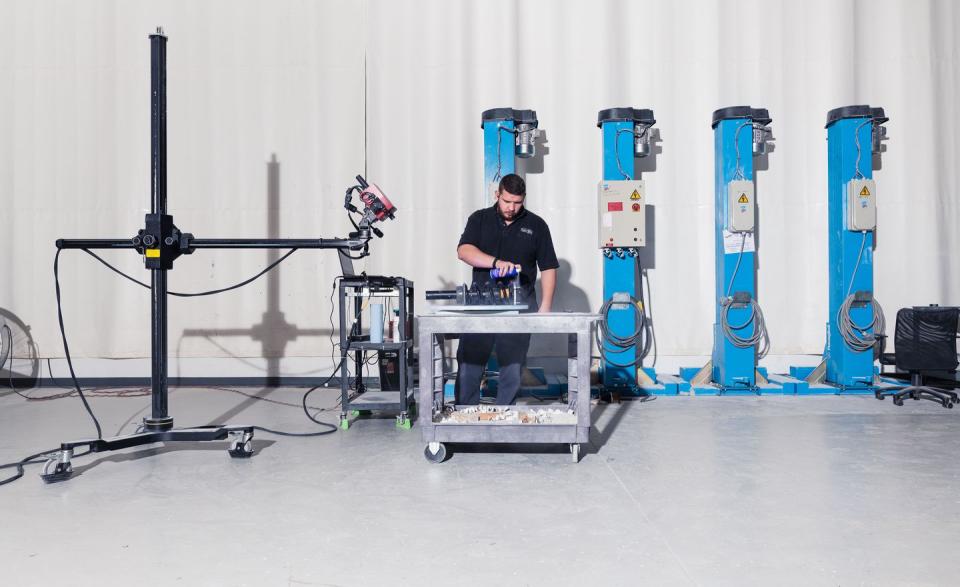

A2Mac1, a France-based company with facilities in China, India, South Korea, Thailand, and Belleville, Michigan, offers a different solution: subscriptions to its static benchmarking services. Annually, A2Mac1 tears apart about 90 new vehicles, a quarter of which are disassembled at its U.S. location. Its employees weigh parts, measure dimensions and clearances with other components, and photograph it all. The company will conduct exclusive teardowns for a fee, withholding the resultant data from other subscribers either indefinitely or for an agreed-upon period of time. And automakers can license A2Mac1's proprietary data-logging software, allowing them to compare their in-house findings with the subscription database. Each participating automaker is required to donate a certain number of vehicles (or the cash to buy them) for every regional market covered in its subscription. A2Mac1's clientele spans nearly the entire industry, from Fiat Chrysler to Tesla.

Think of it as Netflix but for on-demand engineering data instead of episodes of The Office. A2Mac1's people handle the disassembly and data collection but leave any analysis to the automakers. For $150,000 per year, automakers gain access to the company's North America–market data (tapping into global data runs about $2.9 million). Many subscribing carmakers still do their own dynamic benchmarking, the mostly subjective analysis of characteristics such as ride, handling, and aural qualities. Vehicles tested for those attributes are sometimes cared for well enough to be salable at the end of their indentured servitude. A2Mac1's are not.

After disassembly, a car's parts are sent to a storage warehouse, where clients can then check them out, library-style, for "nondestructive testing." The findings can provide critical leverage in a hypercompetitive industry. Engineers can cite rivals' superior part designs to push back against beancounters' cost cutting. Purchasing staff can determine which suppliers their competitors are hiring. Designers can use it to prove that their ambitious ideas could be realized-and that a supplier exists that could execute them.

A2Mac1 also can provide OEMs with 3-D scans of entire vehicles down to the component level. Subscribers may explore the digicars piece by piece or section by section. Videos demonstrating Bluetooth pairing processes, active-safety features, and touchscreen response times are in the works. At least one automaker (A2Mac1 won't say which) has already replaced its internal static benchmarking division with a subscription, and more companies are said to be mulling the switch. After all, when everyone is looking for an edge, advantages don't stay secret for long.

Teardown, Broken Down

1. First, A2Mac1 takes a series of interior and exterior measurements of each donated or purchased vehicle.

2. The company then 3-D scans the vehicle's exterior and interior surfaces.

3. Workers remove and weigh parts, recording where each element was located.

4. Throughout the process, A2Mac1 photographs each part, sometimes with related components attached.

5. The company 3-D scans every part of the car and virtually assembles a full 3-D model of the vehicle using all the digitized pieces.

6. A2Mac1 uploads this information to its database, where users can search for parts, vehicles, and suppliers via a web browser, no special software required.

From the December 2018 issue

('You Might Also Like',)

Yahoo Autos

Yahoo Autos