Mazda’s Gasoline Skyactiv-X SPCCI Engine Explained

Billed as the Next Big Thing for the gasoline engine, Homogeneous Charge Compression Ignition (HCCI) allows for diesel-like operation wherein compression, not spark, combusts lean air/gasoline mixtures for big fuel-economy gains. At least, that’s the theory. Volatile and complex to manage, HCCI’s useful operating window-and efficiency improvements-is limited to low loads: idle or cruising on the highway. Higher rpm and higher engine loads require HCCI engines to revert to spark ignition, an unpredictable, complex process.

For years, HCCI’s challenges have meant that production applications have eluded industry juggernauts such as Hyundai, General Motors, Ford, and Mercedes-Benz. Now, tiny Mazda, the Japanese automaker that has just 2 percent of the global car market, says it will put a compression-ignition gas engine on sale by 2019. Mazda’s Skyactiv-X engine technically doesn’t use HCCI, though, trading that acronym for SPCCI, or Spark Plug Controlled Compression Ignition. Verbiage aside, the end result is the same, compression ignition of a lean air/fuel mixture. Here’s how it works. Nerd alert!-it’s complicated.

To Recap, This Is How Engines Work

Understanding Skyactiv-X is easier with a background in the “suck, squeeze, bang, blow” of the four-stroke gasoline engine’s Otto combustion cycle, a diesel’s operation, and finally HCCI. Let’s begin with the gas engine, which mixes air and fuel during the intake stroke (piston moving down in the cylinder) before igniting it at the end of the compression stroke (piston moving up in the cylinder) using the spark plug. Bang! The power stroke begins, sending the piston back down, transferring the energy of that burning fuel to the crankshaft, spinning the engine. When the piston rises again, the exhaust valve opens and combustion byproducts are pushed out of the chamber and the cycle restarts.

A diesel, on the other hand, ingests and compresses only air during its intake and compression strokes. Combustion is timed not to spark-diesels have no spark plugs-but to the injection of fuel at the end of the compression stroke, which combusts due to the presence of hotter gas created by higher compression in the cylinder. An HCCI engine sits somewhere in between. Although it marries its air/gasoline mixture during the intake stroke as in an Otto-cycle engine, that mix spontaneously combusts due to compression like a diesel.

Mazda’s SPCCI breaks from the experimental HCCI engines that bigger automakers have demonstrated (but never put into production) in that it employs a spark plug to control combustion events. Starting with the intake stroke, an ultralean air/fuel mixture is introduced to the cylinder. The air/fuel ratio varies but is always far greater than stoichiometric, or the ideal 14.7:1 air/fuel ratio, and so lean that it cannot be ignited by spark-hence the need for compression ignition. A baffle on the intake port introduces swirl to the combustion chamber, making the primary air/fuel mixture hug the cylinder wall. At the end of the compression stroke, a second squirt of fuel is injected right next to the spark plug-where it’s held like a bird in the eye of a hurricane by the swirling mixture and quickly ignited by spark. The flame spreads from the plug out and down, creating a pressure wave moving opposite the rising piston. The increase in the cylinder’s effective pressure (not the flame front) combusts the primary air/fuel mixture and initiates the power stroke.

Mazda exerts yet finer control over the blending between spark and compression ignition by altering the flame’s pressure wave using injection- and spark-timing adjustments. Changes to that pressure wave, of course, translate to changes in the effective cylinder pressures, making the Skyactiv-X a de facto variable-compression engine. However, unlike Infiniti’s upcoming Variable Compression-Turbo engine, which mechanically alters its compression ratio (a calculation based on minimum and maximum cylinder volume), the X has a fixed compression ratio but varies each cylinder’s effective pressures.

But How the Hell . . . ?

Naturally, Mazda’s SPCCI began with an attempt to build an HCCI engine. Mazda quickly ran into the same problems as other automakers. Controlling homogeneous combustion events-which amount to otherwise potentially damaging pre-ignition-is difficult without timed spark or injection events, requiring tight control over the amounts of air and fuel in the cylinder, as well as pressures and temperatures. As such, HCCI is intolerant of higher engine speeds and extremely sensitive to variances in atmospheric pressure that come with elevation changes or weather swings.

Get it right, and HCCI will run well, albeit in gentle driving conditions few will ever encounter during pedal-to-the-metal commutes. Transitions back to spark ignition bracketing HCCI’s narrow ideal operating conditions (low engine speeds and under light load) are fraught with issues such as misfires and unwanted pre-ignition or knock. By using spark to control the processes, Mazda solves most of these issues and expands compression ignition’s (CI) operating bandwidth to higher engine speeds and even moderate loads, e.g., acceleration. There still is spontaneous combustion, but per a Mazda engineer, it’s “good knock,” or detonation that initiates or occurs during the power stroke. Compare that with “bad knock,” which is pre-ignition during the compression stroke, the kind that blows up engines. Pre-ignition and knock are different but are often interchanged in conversation. Mazda may call one “good,” but you want neither in your engine.

Another key to running CI more often is a small, belt-driven, Roots-type supercharger that can push a maximum of about 7.0 psi of boost. It isn’t there to increase power; instead, the blower adds more air to the engine for a given amount of fuel, keeping the mixture lean enough for combustion ignition even at higher engine speeds. It is clutched so that it can decouple at lower engine speeds to keep air/fuel ratios from becoming too lean.

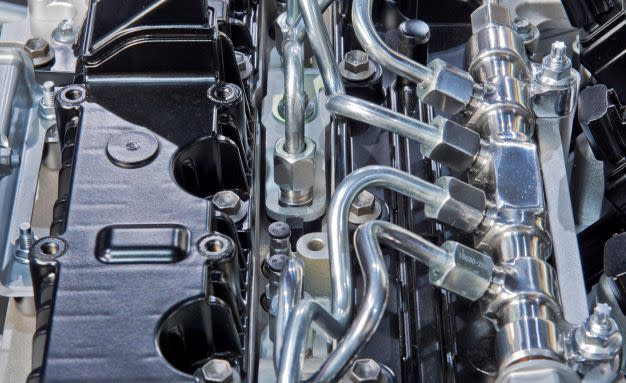

A cooled, electronically managed exhaust-gas recirculation (EGR) system borrowed from the CX-9 helps keep combustion temperatures in check, and whereas the production Skyactiv-G gas four-cylinder engine has variable valve timing on its intake and exhaust sides, the SPCCI system trades the G’s hydraulic exhaust actuation for quicker electric control (like the G, it also uses electronic actuation for the intake side). Since CI operation’s lack of valve overlap can complicate exhaust scavenging, and because the second fuel injection during SPCCI is almost immediately ignited like fuel injected into a diesel engine, Mazda needed a way to minimize soot production. The solution? A high-pressure fuel-injection system that helps the second injection of fuel atomize more quickly for a cleaner burn.

The SPCCI whizbangery, as fitted to a 2.0-liter inline-four, is good for about 190 horsepower and 207 lb-ft of torque. Compare that with the current Mazda 3’s 2.0-liter Skyactiv-G and its 155 ponies and 150 lb-ft. Mazda promises 30 percent greater efficiency, too, and not only on the get-outta-the-way-grandma EPA fuel-economy test cycles. We were shown graphs comparing fuel consumption at different engine speeds and loads for both the Skyactiv-G and the new Skyactiv-X, and while the G’s efficient zone looks like a little splotch between the engine load and rpm axes, the X’s efficient zone looks like someone dropped a big scoop of ice cream on the thing. It’s simply more efficient over a wider range of speeds and loads, because it can run in its modified CI mode.

The implications for Mazda’s corporate emphasis on driving fun abound. Engineers tell us that gear ratios have much less of an effect on the X’s efficiency than on the G’s, allowing for shorter gear ratios that enhance responsiveness while simultaneously encouraging the engine to stay in efficient CI mode with lower loads. But isn’t spinning an engine faster bad for fuel economy? Remember, Mazda can feed enough air to the engine via the supercharger at higher rpm to maintain lean enough air/fuel mixtures for the CI event. Even in spark-ignition mode, the X uses a very lean fuel mixture and employs the Atkinson cycle (or Miller cycle if the supercharger is engaged) wherein the intake valve closes late in the compression stroke to maximize the efficiency of the power (expansion) stroke.

Lacking the heavier engine block, sequential turbocharger, and extra emissions equipment that adds cost to Mazda’s 2.2-liter Skyactiv-D diesel engine, the X is said to be only slightly pricier to build than the Skyactiv-G. In prototype guise, the X shares nothing with the Skyactiv-G, though most of the magic still lies in the X’s software. There are preloaded engine maps for what’s supposed to happen-using spark ignition, CI, or a blend between the two-at given throttle positions, engine speeds, and loads. In practice, the computer checks readings from each cylinder’s knock sensor against these baseline settings and makes any necessary adjustments to the air/fuel ratio and EGR.

Shifting the Squish: Infiniti Takes Recent History’s Biggest Step in Engine Design

Mazda’s G-Vectoring Control: Effective, But Not What Its Name Suggests

There are kinks to work out, namely the noise generated by the so-called “good” knock during transitions between spark and compression ignition, as well as final engine-management tuning and durability testing. But Mazda has two years to get that right. For now, it has a working compression-ignition gasoline engine and a clear plan to put that engine on sale as a premium option above its ubiquitous Skyactiv-G. The little company might be relatively lean, but like the Skyactiv-X, it runs mean.

('You Might Also Like',)

Yahoo Autos

Yahoo Autos