Vintage photos show what it was like to work in a US car factory a century ago

Gas-powered automobiles were first invented in Europe in the late 1800s.

But factories and mass-production techniques soon allowed the US to dominate the car industry.

Photos from 100 years ago show innovations at factories, and what it was like to work in one.

Germany's Karl Benz invented the first gas-powered car with a combustion engine in 1885, and he began selling it soon after. In the first decade of the 20th century, manufacturers turned their focus to creating vehicles that were cheaper to make and sell.

Henry Ford established the Ford Motor Company in Detroit, Michigan, in 1903 and, amid demand for his vehicle, the Model T, he innovated new production techniques, specifically the first moving assembly line for cars in 1913. In the early 20th century, other car manufacturers, such as General Motors and Chrysler, also set up shop in Michigan.

Now, the automotive industry is at a crossroads once again as the United Auto Workers Union, or the UAW, launched a historic strike against three Detroit automakers, Ford, General Motors, and Stellantis, in September. The union is putting pressure on the industry over issues of wages, worker schedules, and benefits.

These black-and-white photos show how car factories looked over the past century.

In the US, the earliest car manufacturers were metalworkers, blacksmiths, and the makers of bicycles and carriages.

Source: Smithsonian National Museum of American History

In the early 20th century, over 100 companies throughout the country were building small numbers of cars powered by electric, steam, and gas.

Source: Smithsonian National Museum of American History

By 1910, Henry Ford had introduced the next model of his in-demand automobile, the Model T, and William Durant had founded his company, General Motors.

Source: History.com

Henry Ford had big plans for improving how his cars were manufactured, so he constructed a new plant in Highland Park, Michigan, in 1910, helping to establish the state as the industry's home.

Source: Ford

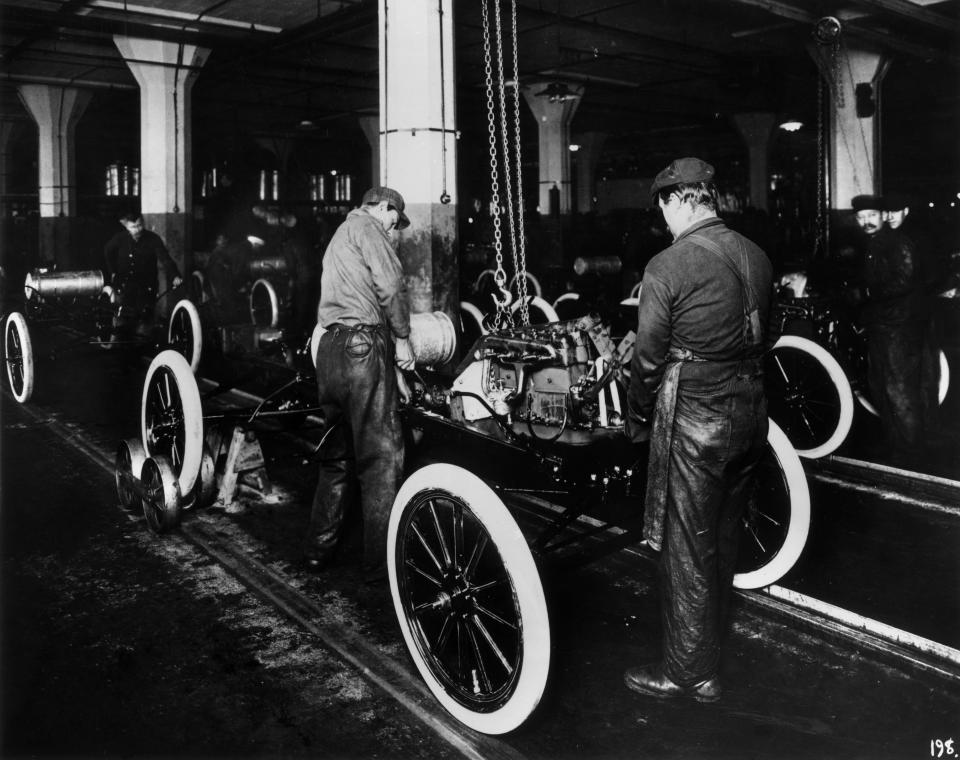

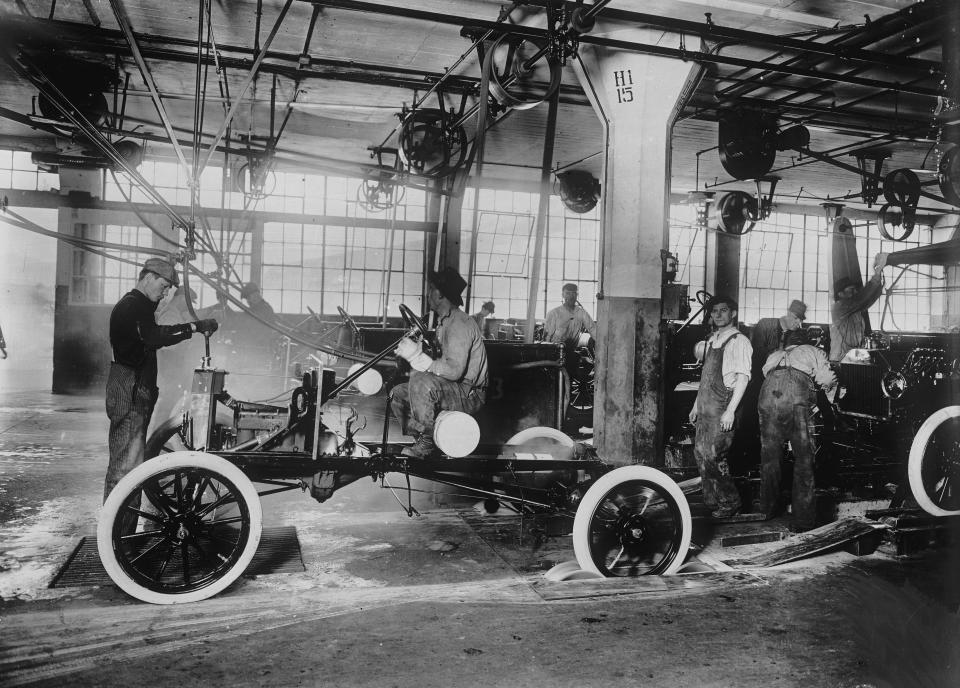

At his plant, Ford innovated mass-production techniques with his moving assembly line, which was first used in 1913.

Source: Ford, PBS

His innovation was inspired by conveyor belts he'd seen in grain warehouses and assembly lines in slaughterhouses.

Source: Ford

The moving assembly line meant the car moved to the employee rather than the other way around. The vehicle was initially pulled into place by a rope — later, a chain — so the car could be built step-by-step.

With the moving assembly line, his Model T could be built in only 93 minutes, a dramatic decrease from the 12 hours it previously took.

Source: Ford

However, the innovation also made employees' jobs more repetitive and tedious — like those pictured making flywheels — and they began quitting in droves.

So in 1914, Ford doubled wages to $5 per eight-hour day, which is about $150 in today's money. This competitive wage and its impact on productivity helped the middle class thrive, NPR reported.

Source: The Henry Ford, Bureau of Labor Statistics, NPR

Yahoo Autos

Yahoo Autos